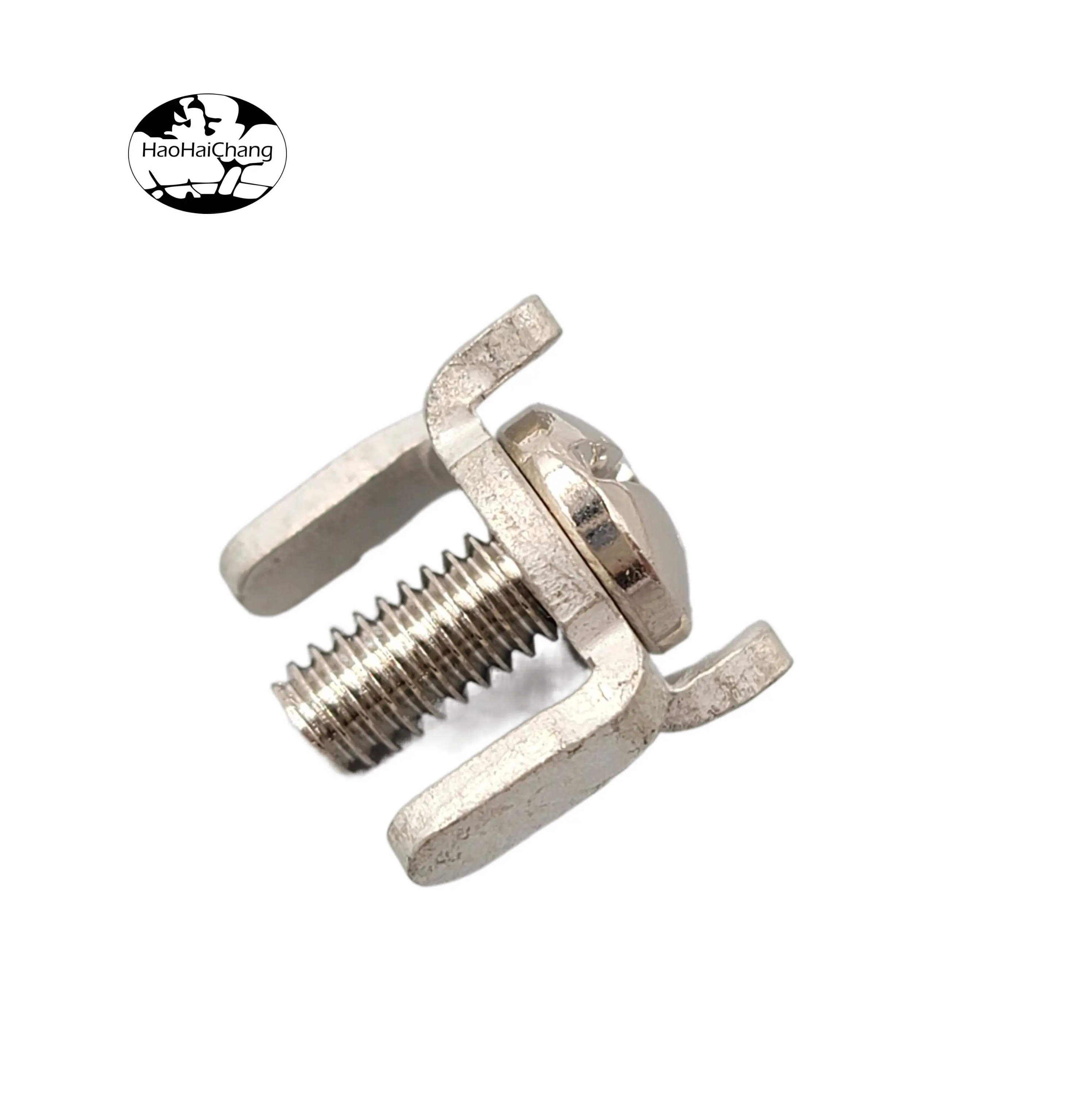

We are HHC Precision, a leading manufacturer specializing in precision metal hardware components. Introducing our latest product, the HHC-416 Custom Copper Tinned Screw Terminal with Bracket for Medical Accessories. Made from high-quality copper with a tinned finish for enhanced durability and corrosion resistance, this screw terminal ensures secure and reliable connections. Designed specifically for medical applications, the bracket provides stable mounting for easy installation. Known for its precision and robust performance, the HHC-416 is ideal for use in medical environments that require high-performance components.

Product Name: | HHC-416 Custom Copper Tinned Screw Terminal with Bracket for Medical Accessories |

Manufacturing Process: | Precision Stamping and Threading,Matte tin plating,CNC Machining for threading |

Base Material: | Brass or Copper |

Surface Finish: | Matte tin plating for enhanced conductivity and corrosion resistance |

Applications: | Electrical wire connections,Power distribution panels,Industrial control equipment, Terminal blocks,Automotive electrical systems,High-current applications |

Screw Thread Diameter: | M4-M6 |

Thread Length: | 8mm-12mm |

Wing Span: | 15mm-20mm |

Wing Thickness: | 1.0mm-1.5mm |

Overall Height: | 15mm-18mm |

Thread Tolerance: | 6g |

General Dimensional Tolerance: | ±0.1mm |

Wing Angle Tolerance: | ±2° |

Surface Treatment Thickness: | 3-5μm |

Color: | Matte Silver (matte tin finish) |

Base Material: | 65-75 HRB |

Thread Hardness: | 80-90 HRB |

Maximum Torque: | 1.2-1.5 N·m |

Operating Temperature: | -40°C to +105°C |

Current Rating: | Based on wire gauge |

Contact Resistance: | ≤2mΩ |

Machining Capabilities: | Precision stamping,CNC threading,Surface finishing,Wing forming, Custom threading available |

Certifications: | IATF16949:2016,ISO9001:2015,ISO14001:2015,RoHS ,Compliant,REACH Compliant |

Packaging Details: | Individually wrapped in plastic bags, then placed in carton boxes with anti-static foam inserts, or as per clients' specific requirements. |

| Shipping Port | Shenzhen or Hong Kong |

| Production Lead Time | |

| Quantity (pieces) 1 - 10,000 | 10 days |

| Quantity (pieces) > 10,000 | To be negotiated |

| Customization Services | |

| Customized logo | Min. order 100(pieces) |

| Customized packaging | Min. order 100(pieces) |

| Graphic customization | Min. order 100(pieces) |