Even with the emergence of new technologies such as 3D printing, CNC machining remains one of the most economical ways to produce goods on demand. This is attributed to the numerous benefits CNC machining brings to businesses, including high-quality parts with low tolerances and precision, as well as fast delivery times. Rapid delivery times ensure that businesses receive ordered parts promptly, thus shortening time to market.

So, what are the factors influencing the cost of CNC machining? How can I save costs? Please continue reading as we provide important information to answer these questions.

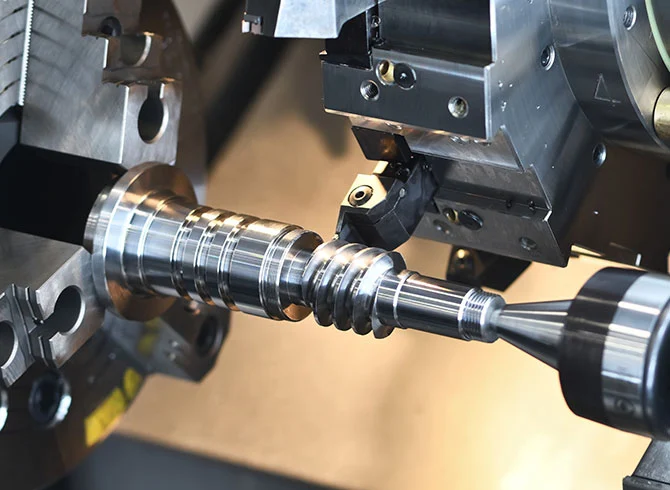

Recognizing the importance of understanding CNC machining costs, it is necessary to delve into the core of CNC machining itself. Computer Numerical Control (CNC) machining is a manufacturing technology that utilizes automated high-speed cutting tools to shape metals and plastics. Examples of standard CNC machines include lathes, milling machines, and machining centers with 3, 4, and 5 axes.

The primary difference among them lies in how they cut the workpiece or part. For instance, the workpiece can move linearly with the tool, rotate and move with the tool, or both the cutting tool and workpiece can move simultaneously.

Computer-Aided Design (CAD) models are used to create geometric information for parts to be machined. Additionally, professional machinists program tool paths for CNC machines based on the geometric shape of the finished machined parts.

Nearly every industry, including medical, aerospace, electronics, and robotics, requires custom CNC machined parts. CNC machines can cut almost any metal alloy and hard plastic with extremely high precision and repeatability.

CNC machining is a complex process involving multiple aspects that directly impact overall costs. Understanding these factors is crucial for businesses seeking to optimize operations and effectively manage expenses. Let's take a look at the key factors influencing machining costs:

Material Selection

Material selection significantly affects the overall cost of CNC machining projects. Factors such as material properties, machinability, and market pricing have a significant impact on costs. High-performance materials like titanium or stainless steel are highly regarded for their strength and durability but are more expensive than plastics or softer metals. Machinability also plays a crucial role; harder materials increase tool wear and machining time, thereby increasing costs.

Furthermore, market fluctuations in raw material prices, supply, and demand can impact costs. Additionally, achieving the required surface finish level for some materials may further increase expenses. Balancing material properties with cost efficiency is crucial in CNC machining to ensure optimal performance and economic feasibility.

Complexity of Design

When it comes to the cost of CNC machined parts or components, part complexity is a major factor. This complexity manifests in various forms, each of which adds to production costs in different ways. For example, complex geometries require intricate CNC programming and precision control, extending setup times and often necessitating the use of more expensive multi-axis machining centers.

The need to achieve tight tolerances is another aspect of complexity that increases costs. Achieving these levels of precision requires not only advanced machinery but also highly skilled operators. This precision-centric process inherently slows down machining operations, thus increasing the time and resources spent on each part.

Additionally, complex features in the design may require specialized tools and methods. These specialized resources are often quite expensive, both in terms of the cost of the tools themselves and the additional time required to effectively use them.

Therefore, the more complex the design, the greater the impact on machining costs due to the combination of advanced equipment usage, skilled labor requirements, and extended machining times.

Production Volume

Batch sizes and quantities in CNC machining directly impact machining costs. This influence has a dual nature. As production volume increases, economies of scale come into play, leading to lower costs per part as fixed expenses such as setup and tooling are spread across more units.

However, striking a balance between setup time and quantity is crucial. In large-scale production, the setup cost per part is significantly lower, allowing for more efficient utilization of setup time and reducing overall costs. Conversely, smaller batches mean that setup costs and time constitute a larger portion of the total expenses, thereby increasing the price per component. Finding the right balance between volume and setup efficiency is crucial in CNC machining.

Manufacturers strive to find production volumes that benefit from economies of scale without resulting in excess inventory or logistical issues. Therefore, optimizing production volume is a strategic choice that significantly impacts the efficiency of CNC machining parts in terms of financial expenditure.

Machine Operating Time

When calculating CNC design costs, machining time is a crucial component. Essentially, the longer the time required to machine a part, the higher the cost. This time includes not only the actual cutting or cycle time but also setup time, which involves tool changes and preparation, along with the overall efficiency of the production process.

Cycle time (the time spent machining the part) may vary significantly depending on the complexity of the part and the type of CNC machine used. Complex parts requiring intricate machining naturally take longer to produce, increasing cycle time and thus costs. Similarly, setup time may constitute a significant portion of the overall machining time, especially for smaller production runs where setup is a vital part of the process.

Labor Costs

Labor costs primarily drive CNC machining expenses, including the wages of CNC machining engineers. Accurate, efficient machining requires skilled operators proficient in CNC setup, programming, and operation. Additional labor costs may be associated with labor-intensive activities or complex part requirements. The key to reducing CNC machining costs lies in balancing budget control and utilizing skilled personnel.

Cost of CNC Machines

Two factors influence machining costs: the upfront cost of CNC machines and their expected annual usage time (typically around 5000 hours). Machinists determine the machine shop rate by dividing the price of the CNC machine by the total annual usage time, often referred to as the per-hour machining cost.

When evaluating CNC machining costs, it's worth considering HHC's CNC machining services. HHC combines cost efficiency and high-quality manufacturing uniquely through advanced technology and professional craftsmanship. Its streamlined process ensures competitive prices while maintaining exceptional standards, making it an ideal choice for fulfilling various CNC machining needs.

Additional Costs

The estimated total cost may be influenced by additional expenses associated with CNC machining processes.

Tooling

When custom CNC manufacturing is required, machine shops often need to use specific cutting tools. While these tools remain in the workshop after production, customers may still bear some of the machine tooling costs. This is primarily due to the wear and tear that the tools undergo during production, a factor that becomes particularly prominent when dealing with high-hardness materials.

The costs involved in purchasing, maintaining, and replacing these cutting tools or inserts are substantial and directly impact the overall machining costs. The lifespan of cutting tools and the time required for tool changes are crucial factors; they not only affect costs but also production efficiency. The regular wear and occasional breakage of tools necessitate frequent replacements, thereby increasing expenses. Therefore, careful selection, ongoing maintenance, and optimization of tooling are key strategies for reducing these costs.

Surface Treatment

Choosing a surface treatment for a CNC machined part is crucial for meeting functional and aesthetic requirements, but it also significantly impacts costs. More complex surface treatments require additional machining steps, specialized tools, and longer time, thus increasing expenses. Conversely, simpler finishes are more cost-effective. Balancing desired outcomes with cost implications is crucial in design and production planning, especially for materials requiring specific finishing techniques.

Timing

The timing of CNC machining not only relates to production efficiency but also to the urgency of customer demands. While advanced high-speed machinery can reduce production time, potentially lowering overall costs, the situation changes when expedited manufacturing is needed. Customers requesting faster turnaround times typically face rush fees, reflecting the additional resources and priority sequencing needed to meet shorter deadlines. This significantly increases costs, especially for large-volume or complex orders. Balancing production speed with these expedited costs is crucial for manufacturers and customers, impacting the final cost of CNC machined parts.

Shipping Costs

Transportation costs are often influenced by various factors, including the size and weight of parts, as heavier items incur higher shipping costs. Additionally, the mode of transportation and packaging are also other factors determining the transportation costs of CNC machined parts, thus determining the total cost of CNC machining.

To reduce CNC costs, a comprehensive strategy that maximizes various areas of the production process is required. Additionally, manufacturers can optimize their cost-saving efforts and improve efficiency by implementing these cost-saving strategies:

Optimizing Design for Improved Manufacturability

When it comes to different products, designing parts for manufacturability is crucial for cost reduction in the application of CNC machining.

This involves designing parts with simpler geometries to reduce complex machining operations and tool wear, thus shortening production time and costs. Adjusting tolerances to practical levels can also significantly reduce expenses. Tighter tolerances often require more precise machining processes, thus increasing costs. Thoughtful material selection and avoiding designs that require extensive and expensive tools are also key.

Collaborating with machining experts during the design phase ensures that designs are not only manufacturable but also cost-effective.

These measures not only streamline the manufacturing process but also optimize material usage and reduce waste. They bring about substantial overall savings while maintaining the quality and functionality of CNC machined parts.

Material Selection and Cost-Benefit Analysis

Choosing materials that balance strength and functional requirements can significantly lower raw material costs. Standardizing materials across product lines can minimize waste, optimize machining efficiency, and simplify procurement. Key considerations for material selection include cost, availability, and machining suitability. This careful approach not only reduces direct material expenses but also enhances overall operational productivity.

Avoiding Multiple Surface Treatments

Some materials require less surface polishing as they are easy to machine. Aluminum is one such material. When these materials are available and feasible, it is advisable to use them. It's worth noting that precision machining processes increase CNC machining costs. Therefore, where mechanical surface finishing can be used, it is preferable, as it is the best CNC machining finish.

However, certain surface treatments are necessary to improve part quality. These include chemical coating, sandblasting, electrolytic polishing, and anodizing. But these finishes should only be used when necessary.

Another factor that increases the cost of surface precision machining is using multiple precision machining on multiple surfaces of a part. For example, some project managers use chrome plating in certain areas and sandblasting in others. Therefore, if possible, try to maintain consistent precision machining standards throughout the entire component.

Leveraging Economies of Scale

Increasing production volume leads to exponential decreases in CNC machining process costs. Let's try to look at this cost-cutting suggestion from a more favorable perspective. Suppose we have a single part worth $40. After producing 10 parts, the unit cost of the part will decrease to about $12.5.

Similarly, if there are 100 parts, the unit cost per part will decrease to approximately $8.79. In summary, by increasing manufacturing orders from 60 to 100 parts, the unit cost per part can be reduced by more than XNUMX%. Because every variable involved in the process remains constant, a decrease occurs. In other words, whether manufacturing ten, fifty, or one hundred parts, the CAD design remains the same.

Additionally, there's no need to choose separate machine configurations for different parts. Choose the same parameters throughout the production process. To maximize economies of scale, consider larger orders to benefit from these economies of scale.

Outsourcing vs Internal Production

The decision between outsourcing and internal production is crucial when weighing options to reduce CNC machining costs. Choosing internal production requires significant investment in purchasing CNC machines and hiring or training skilled operators, leading to substantial upfront and ongoing expenses. In contrast, outsourcing to specialized manufacturers transfers the burden of equipment and labor costs to service providers. You primarily pay for the services provided rather than for the maintenance of machines or labor.

Outsourcing through HHC CNC Machining Services

However, the choice of outsourcing location is crucial. While outsourcing to companies in developed countries may be expensive, companies in regions with lower operating costs (such as China) can offer competitive prices without compromising quality.

For example, companies like HHC in China offer high-quality CNC machining services at only a fraction of the cost compared to their counterparts in more developed economies. This makes outsourcing a viable option for reducing overall machining costs, especially for businesses looking to optimize budgets without sacrificing quality.

When you use HHC, your CNC machining cost calculation becomes straightforward. Our rapid quoting platform allows you to receive quotes almost instantly. We review your design and provide feedback within a day.

We also boast one of the fastest delivery times in the industry, ensuring your products are delivered on time. So why wait? Start your CNC machining project and get a CNC quote!