We are a precision manufacturer specializing in precision metal hardware components. Allow us to introduce our Brass Copper Stamping Parts product: Bracket. Crafted from H65 1/2H brass copper, this bracket boasts is a reliable choice for a wide range of applications where precision and durability are essential.

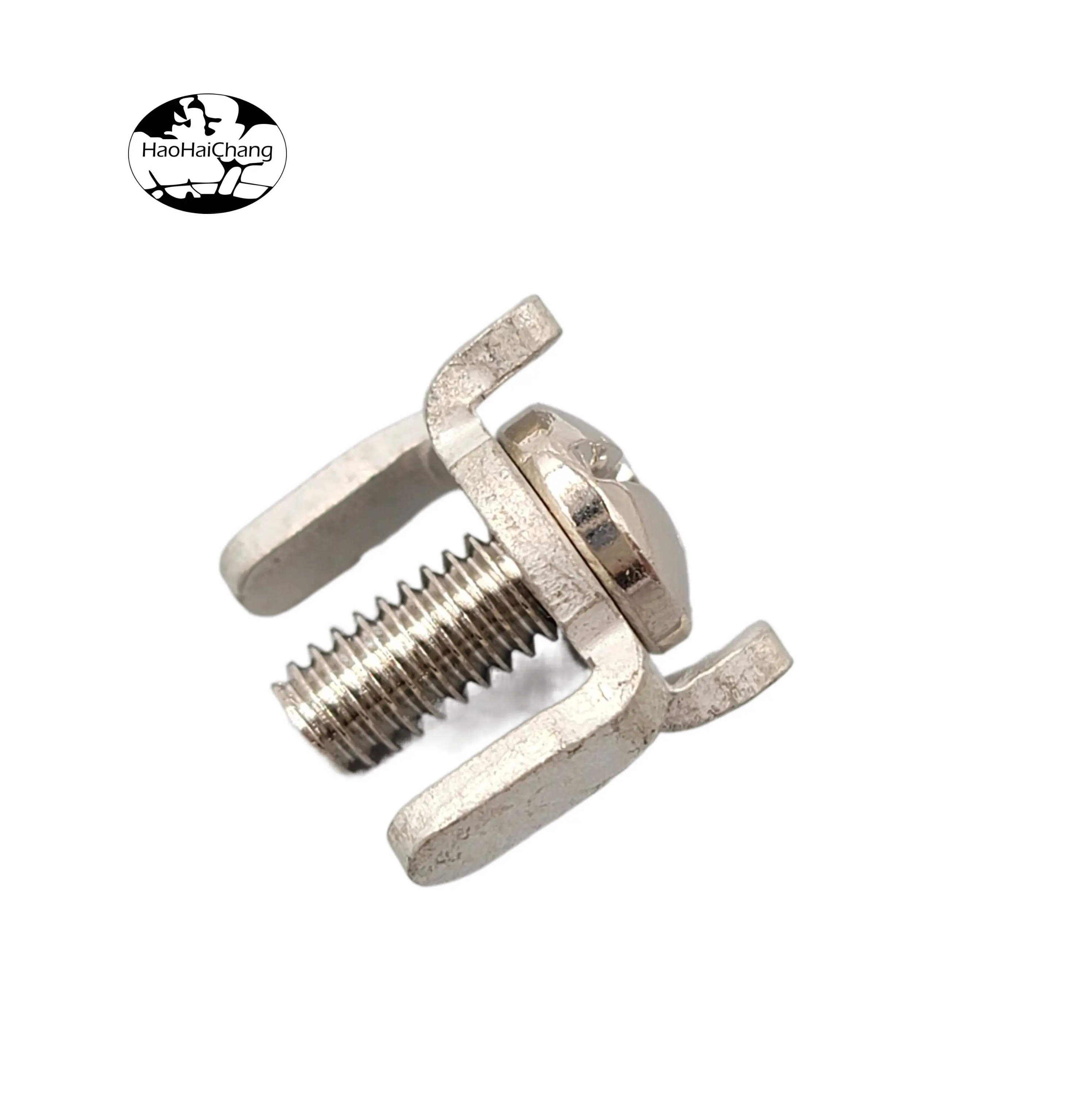

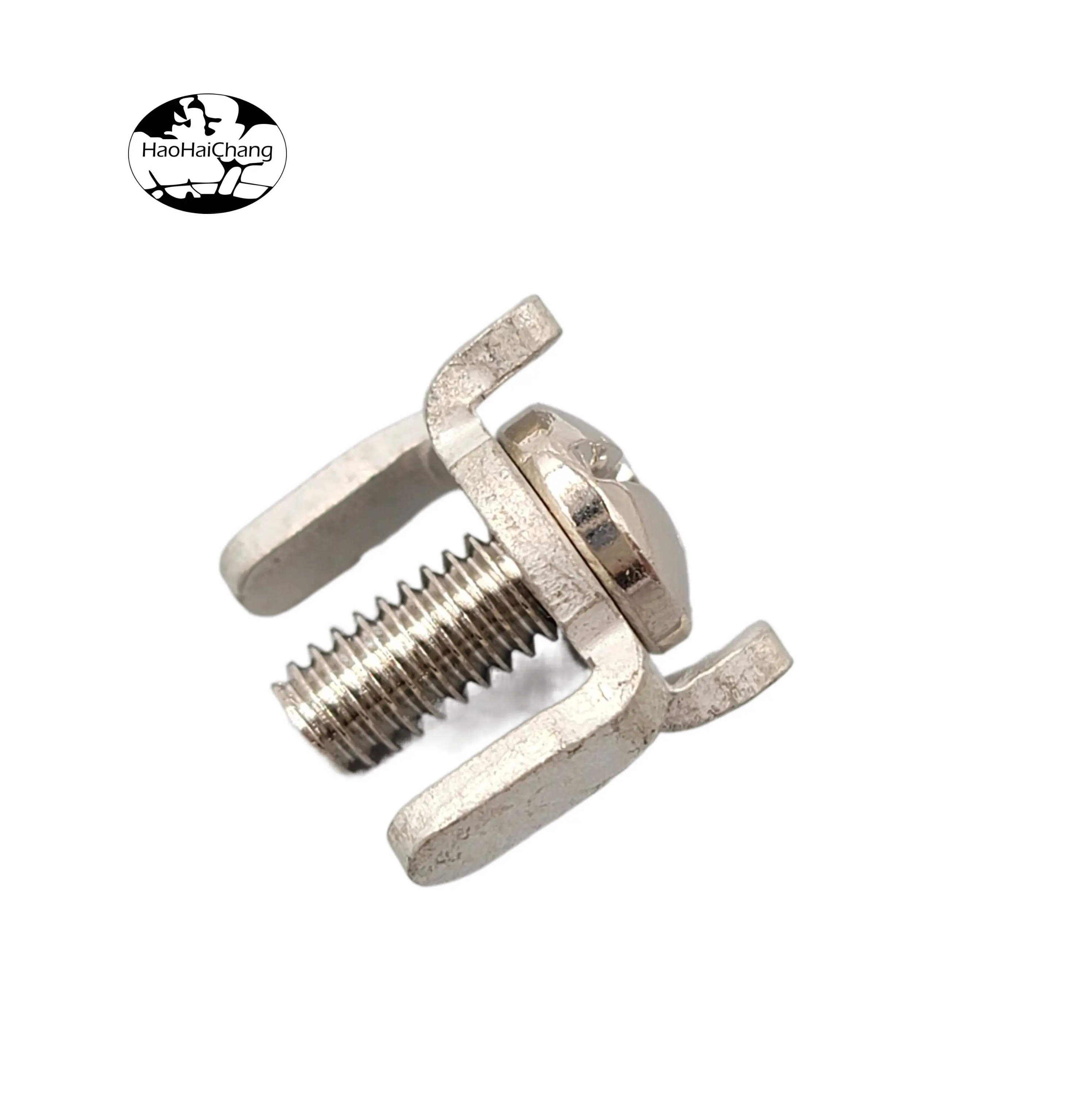

Product Name: | HHC-416 Screw Tinned Copper Bracket Terminal |

Manufacturing Process: | Precision Stamping and Threading,Matte tin plating,CNC Machining for threading |

Base Material: | Brass or Copper |

Surface Finish: | Matte tin plating for enhanced conductivity and corrosion resistance |

Applications: | Electrical wire connections,Power distribution panels,Industrial control equipment, Terminal blocks,Automotive electrical systems,High-current applications |

Screw Thread Diameter: | M4-M6 |

Thread Length: | 8mm-12mm |

Wing Span: | 15mm-20mm |

Wing Thickness: | 1.0mm-1.5mm |

Overall Height: | 15mm-18mm |

Thread Tolerance: | 6g |

General Dimensional Tolerance: | ±0.1mm |

Wing Angle Tolerance: | ±2° |

Surface Treatment Thickness: | 3-5μm |

Color: | Matte Silver (matte tin finish) |

Base Material: | 65-75 HRB |

Thread Hardness: | 80-90 HRB |

Maximum Torque: | 1.2-1.5 N·m |

Operating Temperature: | -40°C to +105°C |

Current Rating: | Based on wire gauge |

Contact Resistance: | ≤2mΩ |

Machining Capabilities: | Precision stamping,CNC threading,Surface finishing,Wing forming, Custom threading available |

Certifications: | IATF16949:2016,ISO9001:2015,ISO14001:2015,RoHS ,Compliant,REACH Compliant |

Packaging Details: | Individually wrapped in plastic bags, then placed in carton boxes with anti-static foam inserts, or as per clients' specific requirements. |

| Shipping Port | Shenzhen or Hong Kong |

| Production Lead Time | |

| Quantity (pieces) 1 - 10,000 | 10 days |

| Quantity (pieces) > 10,000 | To be negotiated |

| Customization Services | |

| Customized logo | Min. order 100(pieces) |

| Customized packaging | Min. order 100(pieces) |

| Graphic customization | Min. order 100(pieces) |