About Connector

We use advanced manufacturing technology and precision machining equipment to ensure that the dimensions of the connectors are accurate and meet engineering requirements. This high-precision manufacturing ensures that the connectors fit perfectly with other instrument components to ensure the stability and precision of dental instruments. Connectors undergo special surface treatments such as polishing, sandblasting or electroplating to increase their corrosion resistance and appearance. These treatments help protect the performance and longevity of the connector during use, while improving the overall quality of the dental instrument.

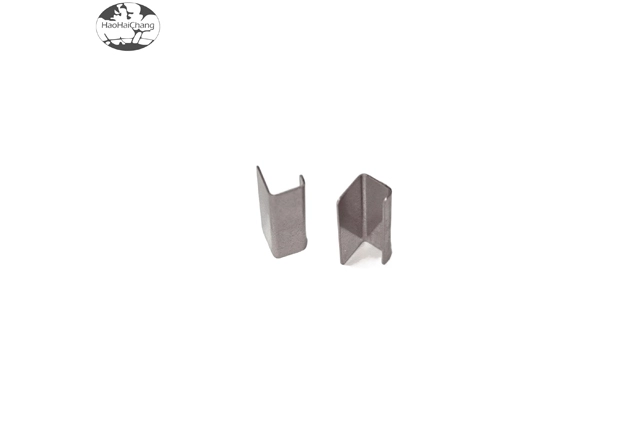

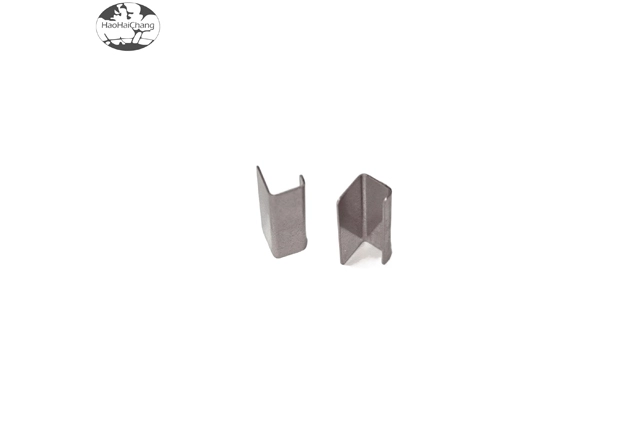

Features of Hardware Accessories Connector Built-In Female Buckle

| Items | Details |

| Product Name | Hardware Accessories Connector Built-In Female Buckle |

| Standard Compliance | OEM Services |

| Certifications | IATF16949 2016; ISO9001 2015; ISO14001:2015; RoHS; REACH |

| Manufacturing Process | Precision Stamping, CNC Machining, Bending, Surface Treatment |

| Applications | Electrical connectors, industrial machinery, home appliances |

| Product Type | Built-In Female Buckle Connector |

| Material Options | Stainless Steel (e.g., 304, 316) |

| Packaging Details | Foam-lined boxes or custom packaging for protection |

| Size Range | Length: 10mm-50mm; Width: 5mm-30mm; Thickness: 0.3mm-3mm |

| Tolerance | ±0.02mm |

| Surface Finish | Polished |

| Color | Metallic Silver |

| Manufacturing Capabilities | High-precision stamping and bending |

| Special Features | Corrosion-resistant, durable, lightweight |

Custom Production Cycles and Export Services of Hardware Accessories Connector Built-In Female Buckle

| Services | Items | Details |

| Shipping Port |

| Shenzhen or Hong Kong |

| Production Lead Time | Quantity pieces 1-5,000 | 10 days |

| Quantity pieces >5,000 | Negotiable |

| Customization Services | Customized Logo | Min. order 50 |

| Customized Packaging | Min. order 10 |

| Graphic Customization | Min. order 50 |