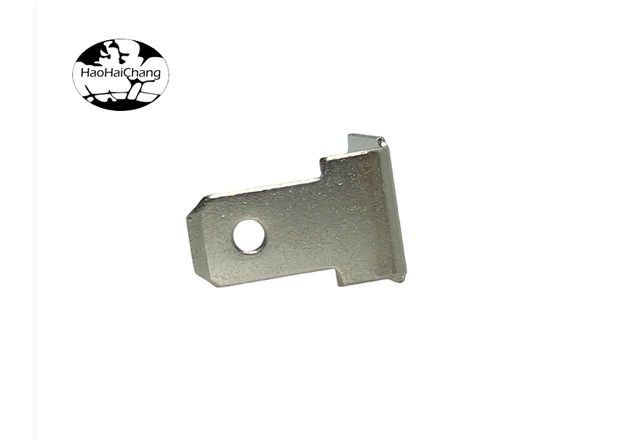

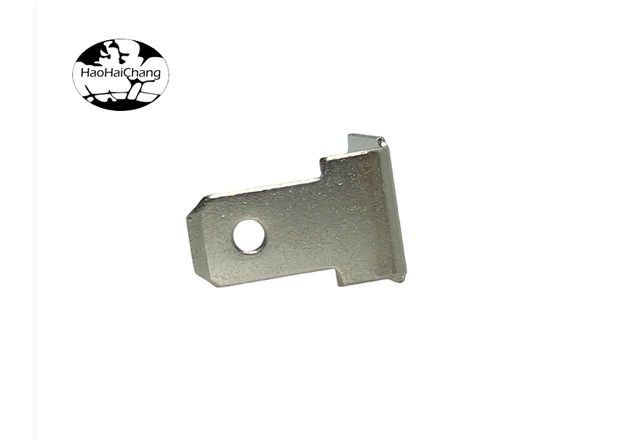

They feature easy installation and maintenance, provide reliable electrical connections, and are widely used in various electrical systems of vehicles. Installing right-angle inserts is usually a simple process and can be done by inserting or securing the connection. In order to ensure good electrical contact and avoid loose wiring, the inserts should be checked and tightened regularly during maintenance.

| Items | Details |

| Product Name | Brass/Copper Stamping Automotive Terminal |

| Standard Compliance | OEM Service |

| Thickness | 0.2-2mm |

| Certifications | IATF16949 2016; ISO9001 2015; ISO14001:2015; RoHS; REACH |

| Manufacturing Process | Stamping/Punching, Forming, Plating |

| Applications | Automotive wiring harnesses, Sensors, Control modules |

| Product Type | Precision Nonstandard Parts (OEM Service) |

| Material Options | Brass, Phosphor Bronze |

| Packaging Details | |

| P | a |

| Additional Product Specifications | |

| Dimensions | 5mm - 40mm (length), 2mm - 15mm (width) |

| Tolerance | ±0.03mm |

| Surface Finish | Nickel Plating,Tin plated, Silver plated, or Gold plated |

| Current Rating | Up to 20A (depending on design) |

| Wire Gauge Compatibility | 18-28 AWG |

| Temperature Range | -40°C to 125°C |

| Vibration Resistance | Meets automotive standards (e.g., ISO 16750-3) |

| Services | Items | Details |

| Port | Shenzhen or Hong Kong | |

| Lead time | Quantity (pieces) 1 - 10,000: 12 days | To be negotiated |

| Lead time | Quantity (pieces) 10,001 - 50,000: 18 days | To be negotiated |

| Lead time | Quantity (pieces) > 50,000: To be negotiated | To be negotiated |

| Customization | Customized logo: Min. order 5,000 pieces | Min. order |

| Customized packaging: Min. order 10,000 pieces | Min. order | |

| Graphic customization: Min. order 5,000 pieces | Min. order |