We are a precision manufacturer specializing in precision metal hardware components. Allow us to introduce our Aluminum Stamping Parts product: Bracket. These brackets, crafted from 5754H22 aluminum, measure 0.8×80×28.5mm and serve the industrial research, design, and manufacturing accessory industry with exceptional quality and precision.

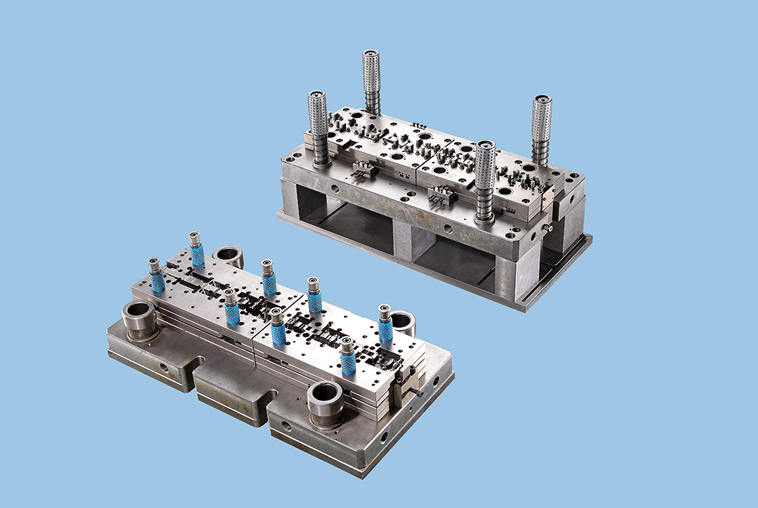

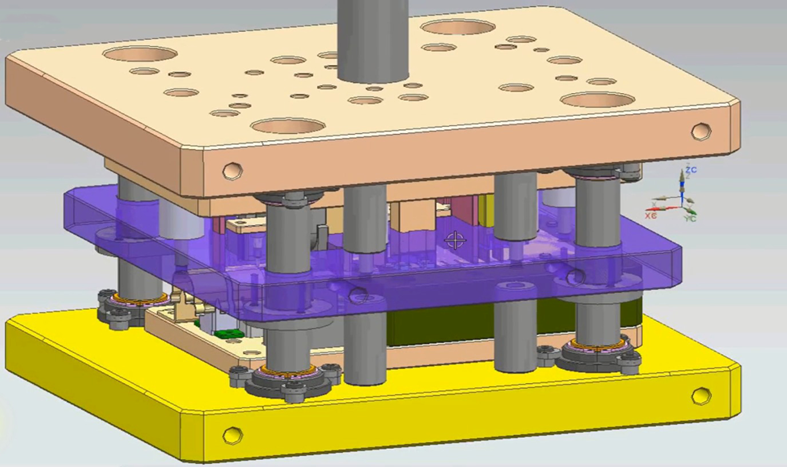

When you place an order for an aluminum table, the business process will initiate the formal order in our business system. Depending on the product production plan, customized molds may or may not be required. If necessary, we will design and manufacture the customized molds, and procure the raw materials. Custom mold production involves wire cutting, drilling, threading, heat treatment, and finishing. The entire mold production process, from design to completion, typically takes 1-3 weeks. After the engineering segmented processing and assembly are completed, the engineering department collaborates with the technical, quality, and production departments to create trial production samples. Once the specified quantity and continuous production hours are achieved, and the samples pass the quality tests, the molds are transferred to the production department for mass production. The production department schedules mold setup and materials issuance based on the issued work orders to produce the products.

Material Selection: Our metal stamping process utilizes high-quality metal materials, including copper, aluminum, iron, and stainless steel sheets, among others. The choice of materials depends on the product requirements, and we will provide the most suitable metal material based on your needs. Our collaboration with suppliers is extensive and reliable, ensuring controlled lead times.

Mold Design Repository: In our metal mold repository, we have a wide range of specialized custom metal mold solutions. Decades of accumulated experience have allowed us to develop expertise in various custom punching molds, composite blanking molds, bending molds, riveting molds, blanking molds, side punching molds, deep drawing molds, terminal molds, progressive dies, and more. We offer a variety of single-operation molds, continuous molds, and compound molds. At Haohaichang, we can tailor the production plan to your product specifications and design specialized stamping molds. These molds will guarantee high-precision production and consistent product quality.

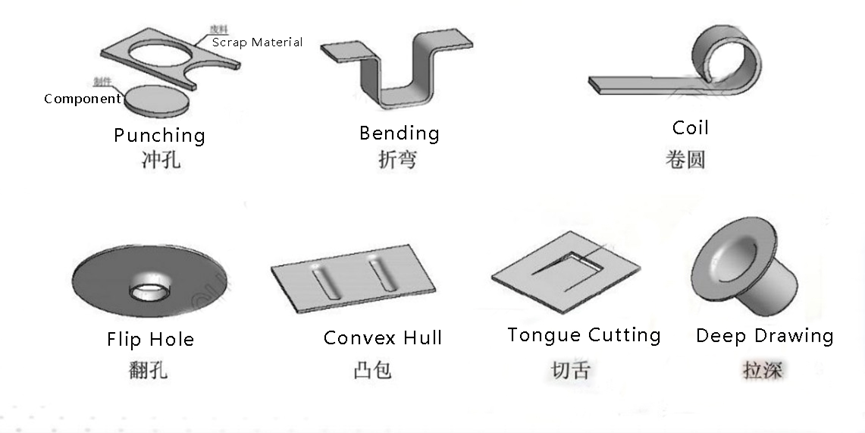

Advanced Stamping Equipment:Our stamping process encompasses a wide range of techniques, including blanking, punching, bending, stretching, shearing, notching, edging, cutting, flanging, shaping, perforating, and more. We are equipped with various state-of-the-art punch press machines that can apply highly controlled pressure to ensure product precision and consistency. Coupled with comprehensive post-processing operations such as threading, chamfering, riveting, electroplating, engraving, heat treatment, pickling, and more, our equipment can handle a variety of dimensions and complexities for metal components, as illustrated in the diagram below:

Precision Stamping Operations: Our experienced operators use advanced techniques for precision stamping operations to meet your product specifications. Stamping operations typically involve multiple strikes to gradually shape the metal, ensuring the accuracy of the final product.

Quality Assurance: Our products undergo a comprehensive quality assurance process, starting with incoming material inspection (IQC), in-process inspection (IPQC) during production, and final inspection (FQC) at various stages of the manufacturing process, culminating in outgoing quality control (OQC) checks. We have a well-established product inspection system and utilize complete testing fixtures. We follow stringent quality control procedures, including the use of high-precision measuring tools to inspect product dimensions and quality, ensuring that your products meet the highest standards.

Customized Service: Whether you need to manufacture automotive components, electronic equipment casings, or other hardware products, we can provide customized metal stamping solutions tailored to your requirements.

If you are seeking a reliable metal stamping manufacturer, we possess advanced equipment, an experienced team, and professional mold design capabilities to meet your needs. Please feel free to contact us for more information or request a quote.

As a professional metal stamping product manufacturer with decades of experience, Haohaichang possesses significant advantages and characteristics. Taking aluminum stamping products as an example, we offer the following advantages and characteristics:

Customization Capability: Leveraging our years of experience, we can meet various specific customer requirements. Whether it's about shape, size, or specific production processes, we can provide customized aluminum stamping products. This means that customers can obtain tailored solutions that perfectly match their project needs, whether it's for small-scale or large-scale production.

Technical Expertise: We have extensive experience in the field of metal stamping and exceptional technical capabilities. We employ advanced production equipment and processes, including a variety of stamping machines with capacities ranging from 25t to 165t. This ensures that our products have high quality and precision. It enables us to tackle highly technical and complex projects while delivering outstanding product performance.

Quality Management: Quality management has always been at the core of our operations. We employ stringent quality control processes to ensure product consistency and reliability. This helps meet customer quality expectations and reduces the risk of producing non-conforming products.

Cost Efficiency: With our self-owned industrial park, we can achieve higher production and operational cost efficiency. This enables us to offer competitive pricing while maintaining high product quality and reliability. Customers can benefit from our production expertise and cost efficiency, ultimately reducing the overall project costs.

Supply Chain Control: The advantage of having a self-owned industrial park also extends to better supply chain control. We can more effectively manage raw material procurement, production schedules, and delivery times to meet customer timelines and urgent demands.

Environmental Awareness: In the context of increasing environmental consciousness, we adhere to strict environmentally friendly production practices to ensure production sustainability. Our commitment to green and eco-friendly products enhances the competitiveness of our products in the market.